types of capacitor

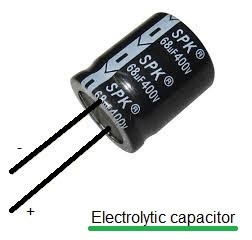

Electrolyte capacitors

Generally, the electrolyte capacitors are used when the large capacitor values are required. The thin metal film layer is used for one electrode and for the second electrode (cathode) a semi-liquid electrolyte solution which is in jelly or paste is used. The dielectric plate is a thin layer of oxide, it is developed electrochemically in production with the thickness of the film and it is less than the ten microns.

Mica Capacitor

This capacitor is a group of natural minerals and the silver mica capacitors use the dielectric. There are two types of mica capacitors which are clamped capacitors & silver mica capacitor. Clamped mica capacitors are considered as an obsolete because of their inferior characteristic. The silver mica capacitors are prepared by sandwiching mica sheet coated with metal on both sides and this assembly is then encased in epoxy to protect the environment. The mica capacitors are used in the design calls for stable, reliable capacitor of relatively small.

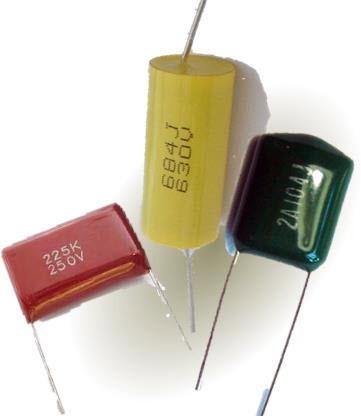

Film Capacitor

The film capacitors are also capacitors and they use a thin plastic as the dielectric. The film capacitor is prepared extremely thin using the sophisticated film drawing process. If the film is manufactured, it may be metalized depend on the properties of a capacitor. To protect from the environmental factor the electrodes are added and they are assembled.

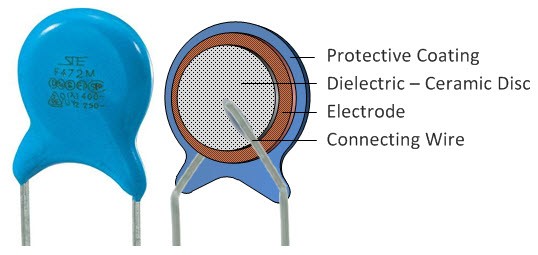

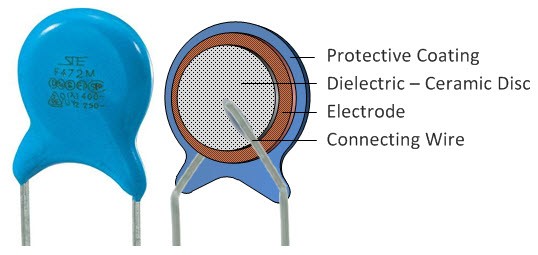

Ceramic Capacitor

The ceramic capacitors are the capacitors and use the ceramic material as a dielectric. The ceramics are one of the first materials to use in the production of capacitors as an insulator.

Ceramic Capacitor

There are many geometries are used in the ceramic capacitors and some of them are the ceramic tubular capacitor, barrier layer capacitors are